Artificial intelligence is often discussed in the context of personal devices or services, such as home assistants like Amazon Echo or Google Home. However, there is a growing trend of using industrial artificial intelligence or industrial AI.

The industrial sector has always been a heavy consumer of electricity. Factories run around the clock, 365 days a year. Machinery needs constant cooling and maintenance engineers to avoid perilous breakdowns. All this activity comes at a cost, and it’s not just the electricity bill. The need for human maintenance and oversight can also lead to higher costs and slower production times.

This is where artificial intelligence (AI) comes in. Factories are incorporating machine learning algorithms to help with predictive maintenance, robot automation, and quality control.

What does AI mean for the industry?

Industrial AI, also known as operational AI, is an application of artificial intelligence that helps companies optimize and automate their industrial processes. The ultimate goal of industrial AI is to help industries run smoothly and achieve increased productivity, all while reducing costs.

According to a report, AI adoption by the industry has surged from 19% to 31% over the last two years. Moreover, the number of domain vendors has increased twofold, compared with 2019. Today, artificial intelligence in the manufacturing market is backed up by key tech scions, including AWS, IBM, Microsoft, and others.

A growing industrial AI market size and tech boom have also ushered in a new phenomenon of Industry 4.0. Industry 4.0, also known as the fourth industrial revolution, is a term that describes automation and data exchange baked into manufacturing technologies. The uptake of industrial AI is also a part of Industry 4.0.

Source: Unsplash

Besides industrial AI services, Industry 4.0 also comprises cyber-physical systems, the Internet of Things (IoT), cloud computing, Big data analytics, and others. Together, this suite of technology offers countless opportunities for manufacturers to optimize their operations and increase efficiency.

The benefits of industrial AI software

Global manufacturers leverage machine intelligence to strengthen their production lines. The BMW Group is among great advocates of AI and uses it in all areas – from production to customer services. General Motors applies intelligence to power computer vision on site. Nissan has fully automated its smart factory with industrial robotics powered by computer intelligence. But what makes industrial AI platforms so beneficial for manufacturers? Let’s see.

Automation

First and foremost, manufacturers leverage AI for industrial automation. Intelligent systems can take over both complex and simple tasks, thus reducing operational costs and human presence at all stages of production.

Porsche, for example, employs autonomous guided vehicles (AGVs) to automate large parts of the automotive production process. The AGVs transport car body components from one processing station to the next, removing the need for human interaction and allowing the plant to stay resilient through the pandemic.

24/7 production

Unlike human beings, machine learning and AI do not need breaks, vacations, or sleep. Industrial AI platforms don’t get tired or hungry and are capable of working on the production line at all times of the day. The round-the-clock coverage allows industrial AI companies to grow production capabilities, thus meeting the growing customer demand.

Source: Unsplash

Improved safety

Another benefit of AI in the manufacturing industry is enhanced product safety. Thus, predictive algorithms can help avert possible faults in equipment and reduce on-site accidents. Computer vision can also prevent injuries and the absence of PPE to promote industrial workplace safety.

Accurate supply/demand ratio

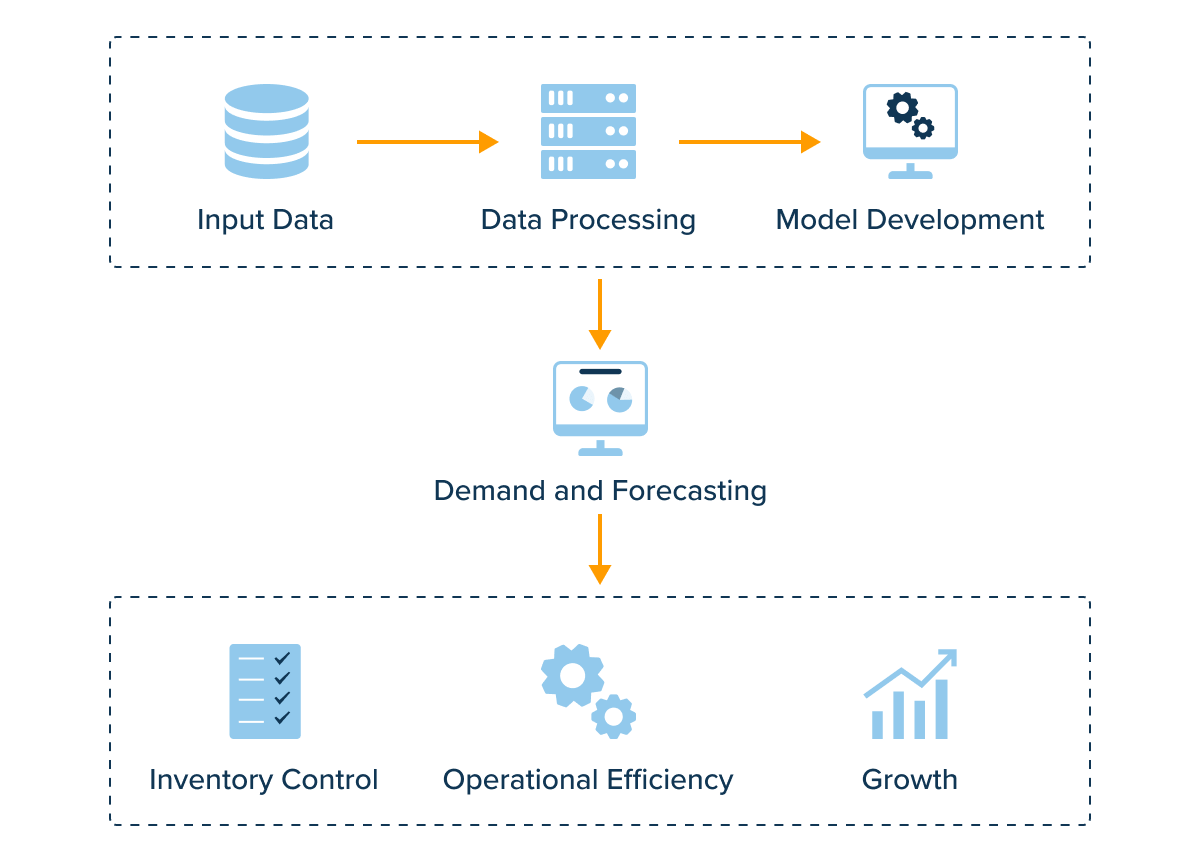

AI-powered demand forecasting allows companies to predict changes in consumer demand. This predictive power has been especially relevant for manufacturers during the pandemic-induced demand imbalance.

The growing prices of raw materials also encourage companies to estimate the forecast of customer demand. By analyzing historical data and current trends, machine learning algorithms allow for more certainty in supply chain planning.

Source: Unsplash

Reduced costs

Summing up, industrial AI software leads to a higher return on investment and optimized costs. AI industrial applications take labor-intensive processes and avert costly machine failures. They also enable companies with more data intelligence, promoting accurate business decisions. According to Deloitte, intelligent automation cuts business process costs by up to 40%.

Top AI industrial applications in 2022

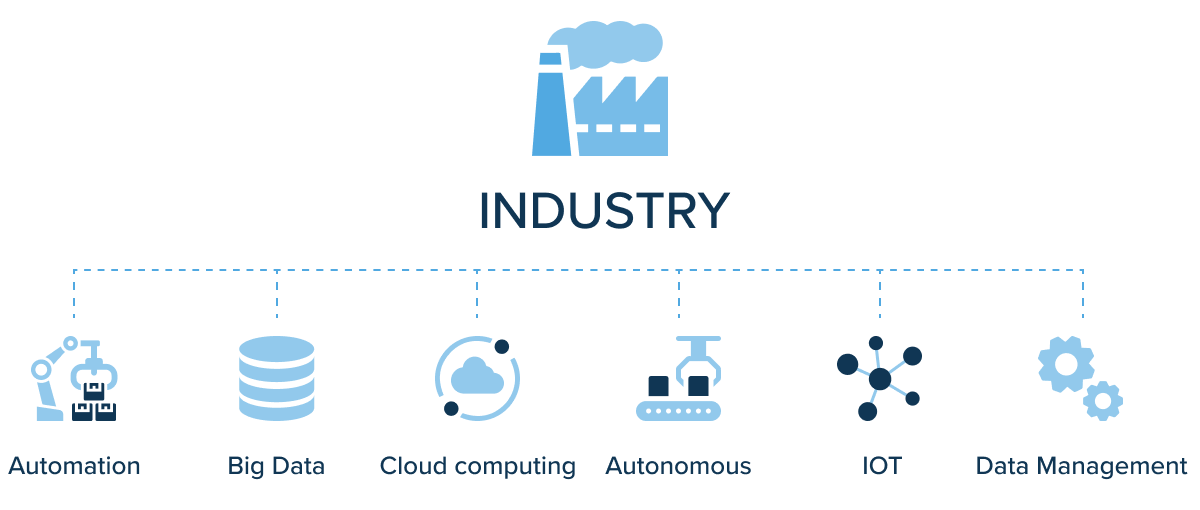

If we look at the AI adoption by industry chart, we’ll see that manufacturing lags behind other industries. Thus, AI adoption by industry climbed to 4% in 2021, while fintech scored 15%. Despite the slow uptake, industrial artificial intelligence companies have already seen a variety of use cases. Below, we’ll go over the latest AI developments for industrial use.

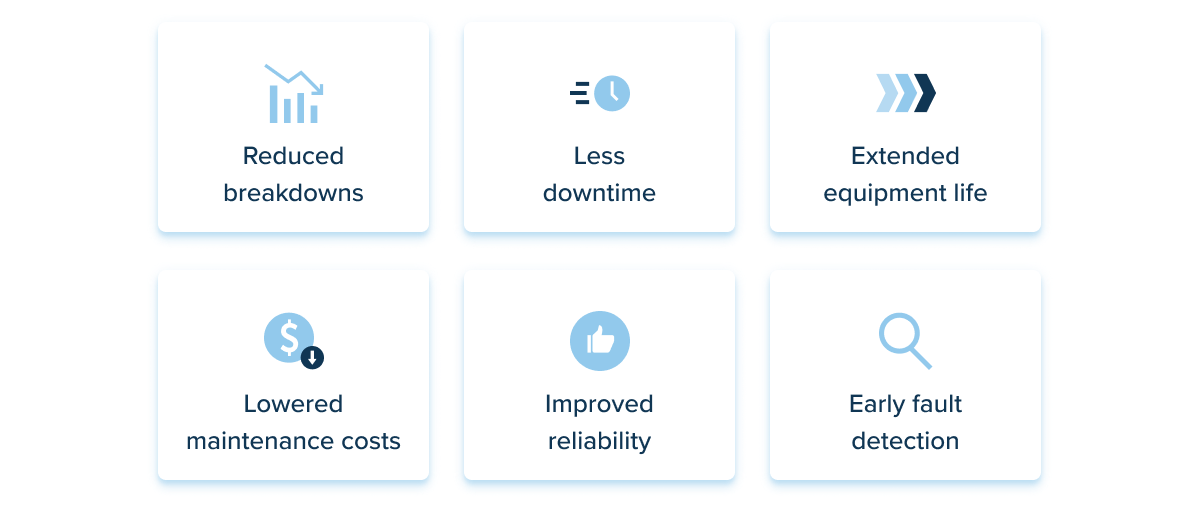

Predictive maintenance

Today, many companies invest in proactive maintenance as a way to avoid additional expenses and improve operations. Predictive maintenance is powered with analytics and historical data. Both allow the system to predict when a particular machine or device will fail.

As the report suggests, over 40% of respondents have already started implementing machine learning services and solutions for maintenance operations. According to another source, predictive maintenance boosts productivity by 25%, reduces breakdowns by 70%, and lowers maintenance costs by 25%.

This trove of benefits secured the upward tendency of this application. By 2026, the predictive maintenance market is expected to grow by $15.9 billion.

The BMW Group is a prominent example of top-grossing productions that leverage predictive maintenance. The car manufacturer uses a combination of sensors, data analytics, and artificial intelligence to monitor the current condition of machinery and prevent system failures.

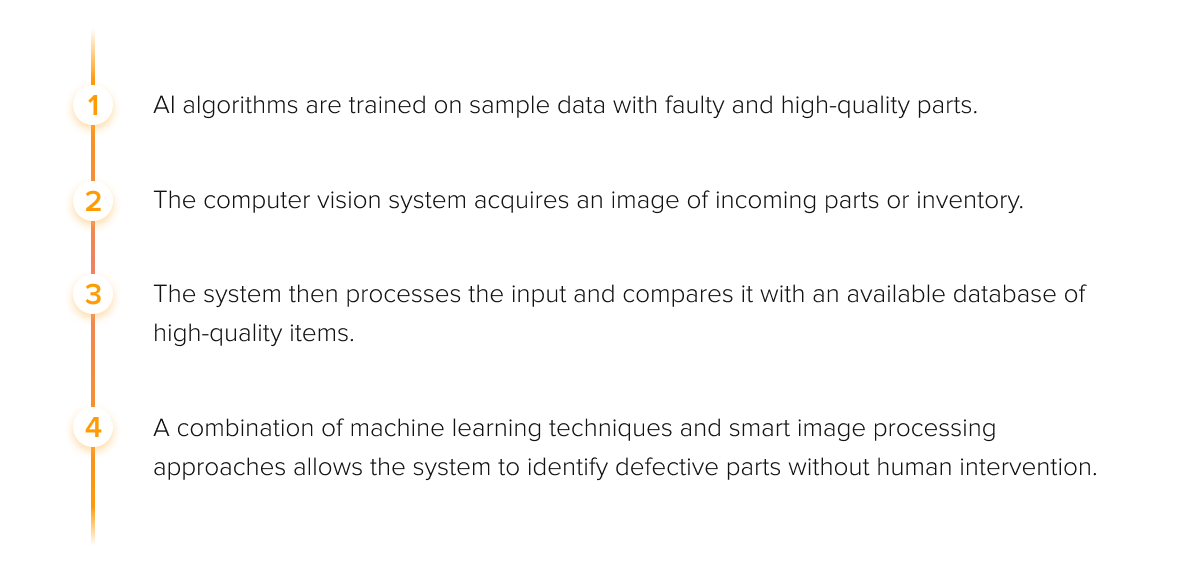

Quality control

Factories have long used manual approaches to sorting production. However, with the advent of machine learning, quality control can be farmed out to machinery. In this way, industrial AI can be used as an inspection tool that automatically searches for defects, increasing the overall quality and efficiency of production.

Source: Unsplash

Typically, quality assurance is carried out through computer vision systems. The latter is complemented with intelligent algorithms to process generated data.

Expected benefits:

- improved inspection measurement reliability

- reduced costs of quality control

- enhanced quality of the final product.

As a result, intelligent fault detection helps companies reduce costs and improve the quality of the final product. Already in 2017, IBM Watson was hired for inspection analysis at one of the factories. According to the data by IBM, Watson was able to cut 80% of the inspection time while reducing manufacturing defects by 7-10%.

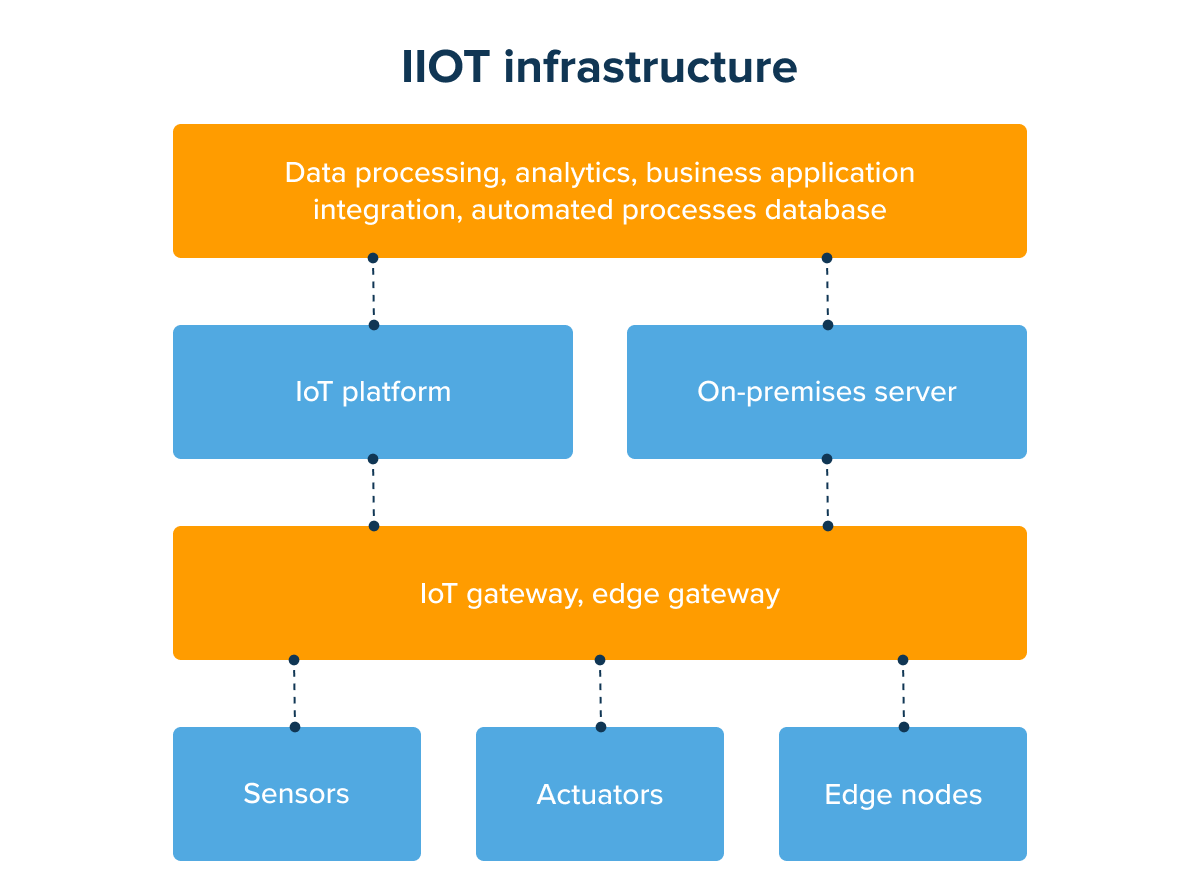

Industrial IoT and AI

The industrial Internet of Things or IIoT is a rapidly growing field that applies the Internet of Things to industrial settings. This encompasses everything from oil refineries and power plants to assembly lines and parking garages. The IIoT enables these industries to collect and analyze data in real-time, leading to increased efficiency, safety, and productivity.

Source: Unsplash

One important application of the IIoT is the combination of industrial IoT and AI to enable factories and other industrial facilities to operate autonomously. In layman’s terms, this combination can be presented as a human body. IoT data is a digital nervous system, while artificial intelligence is the brain of IIoT.

The foundation of IIoT is massive amounts of data. The latter is collected at high frequency and is made accessible across IoT platforms and servers. Machine learning services and solutions then process, analyze and make sense of the collected IoT data. As a result, manufacturing sites get an omnipresent network of data processing and artificial intelligence decision-making across all stages and departments.

Smart logistics

The production process doesn’t end on a production line. Once the output is ready, it needs to be distributed to the final buyer or intermediary that sells the product to the customer.

Logistics artificial intelligence, can improve the efficiency of supply chains and dramatically reduce the cost of transportation. With AI, industrial AI companies can optimize the movement of goods to respond to real-time changes in demand and create a global logistics network that is smarter and faster.

Essentially, smart logistics relies on effective data processing to enable intelligent traffic systems and logistics management. From a technical perspective, this concept mandates a network of sensors, industrial AI services, and data analytics. Machine learning in logistics is then used to aggregate this patchwork of data to generate forecasts.

For example, DHL leverages the benefits of AI in the automotive industry by using smart trucks with sensors. A sensor ecosystem allows the company to track cargo in real-time as well as remotely monitor the temperature. DHL SmarTruckings operations staff then receives updates via mobile apps and can use this information for route and delivery planning.

Inventory management

Inventory tracking refers to a wealth of activities that aim to manage the movement of all physical assets required to produce goods. Industrial inventory management has always been a dread for manufacturers. Inconsistent tracking, changing demand, and limited visibility lead to incomplete, inaccurate, or delayed shipments. This, in turn, results in financial losses and a damaged reputation.

Source: Unsplash

To avoid the aftermath of poor inventory, 61.3% of companies adopt forecasting as the main inventory management practice. AI for industrial automation is what fuels the forecasting abilities of inventory tracking.

AI-powered inventory management systems can optimize stock levels and minimize waste due to overstocking or out-of-stock. Additionally, they can help businesses identify patterns in customer demand and make better predictions about future demand. This allows businesses to stock the products that their customers are more likely to want, improving sales and reducing the amount of money lost on unsold items.

Industrial robotics

Once a far-fetched dream, industrial robotics has entered mainstream industrial AI use cases. The market was valued at around $24 billion in 2020. By 2026, it is slated to reach $ 52.85 billion.

While robots may have once been used only for heavy-duty or repetitive tasks, they are now being relied on to complete a wider variety of jobs. In some cases, robots are performing tasks that were once done manually by human employees. Warehouse robots, for example, take over essential warehouse tasks, including picking, sorting, and transportation.

Amazon, the world’s largest retailer, has over 20,000 robots working in its warehouses. Cainiao, a Chinese logistics firm, has also opened a warehouse with over 700 robots working in it to handle cargo transportation and other tasks.

Besides warehouses, robots can outnumber human workers in repetitive manufacturing processes. These may include automated processing (polishing, carving), dispensing, and assembly.

Introducing industrial AI to manufacturing

According to Deloitte, 93% of companies believe AI will be the crucial force behind manufacturing. However, automation cannot be built overnight. Below, we’ve collected the milestone toward industrial AI.

Foster a cultural shift

Having industrial artificial intelligence handle manual tasks means that your personnel have to rely on industrial AI systems. Therefore, manufacturers should educate employees on the value of automation and dwell on the limitations. Documentation and knowledge sharing should prompt full adoption.

This way, your employees can plan for the future and be immune to technological failure.

Prep the data ground

Any type of AI software development is powered by data. Therefore, the AI ML industry is premised on consistent, full, and clean data that flows from a unified data collection system. Sensor data should also be stored in data lakes and be accessible for industrial AI applications.

Decide on the business case

Not all tasks are subject to automation. Manufacturers should perform a thorough audit of internal processes and assets to define the most relevant short, medium, or long-term use cases. Each case should be audited for ROI and automation potential.

Source the necessary AI talent

A full-throttle adoption of artificial intelligence requires relevant expertise. Therefore, manufacturers need to assess the skills already present in the workforce and identify gaps.

As a rule, the AI implementation necessitates the guidance of data scientists, data engineers, and machine learning developers. If this talent isn’t available in house, companies can turn to machine learning consulting providers.

Making manufacturing automated

The growth of the AI industry is resonating down all verticals. The industrial AI market size has also gained momentum with $2.3 billion in value in 2022. A competitive asset, automation complements all stages of manufacturing workflow – from supplier selection to shipping. In the coming years, the industrial artificial intelligence revolution is expected to accelerate as Industry 4.0 becomes the main priority for manufacturers worldwide.

Amplify the manufacturing industry with AI solutions

Schedule an intro call with our AI consulting experts to explore your business and find out how we can help.