The AI revolution has reenergized manufacturing and has had a transformative impact on businesses globally. More precise, qualitative, and faster products became possible using AI solutions for manufacturing to improve productivity.

Besides AI product management, artificial intelligence capabilities are extremely high and ample for different cases like AI consulting, AI in automotive manufacturing, and AI for companies. Industrial companies utilizing AI don’t eliminate the chances of applying AI in their business domains to determine effective workflows. According to statistics, more than 80% of companies integrate AI efficiency factory automation.

Source: Unsplash

The embracement of AI solutions in fabrication comprises quality control, supply chain optimization, design products, and demand estimation. AI increases efficiency and productivity quickly. This is beneficial for companies to maintain a competitive edge in the industry and keep up with the times in an ever-changing environment.

Manufacturing companies can take advantage of artificial intelligence capabilities. Integrating AI tools will streamline the entire process and boost production output. Let’s have a look at the main advantages of AI for improved productivity in Manufacturing and why companies implement AI in their fabrications.

Top benefits of AI in manufacturing

The ability of AI not only drives innovation but also shapes the future of manufacturing by enabling smarter, faster, and more sustainable production methods. By integrating AI benefits into manufacturing, companies are experiencing significant efficiency, quality, and cost-effectiveness improvements.

Enhanced supply chain management

AI technologies facilitate smarter supply chain management by providing immediate insights into amounts, shipment tracking, and demand prediction. AI algorithms can analyze changes in market and consumer behavior, enabling manufacturers to adjust their supply chains effectively. This agility not only enhances operational productivity but also mitigates risks associated with disruptions, such as shortages or delays.

Improved safety

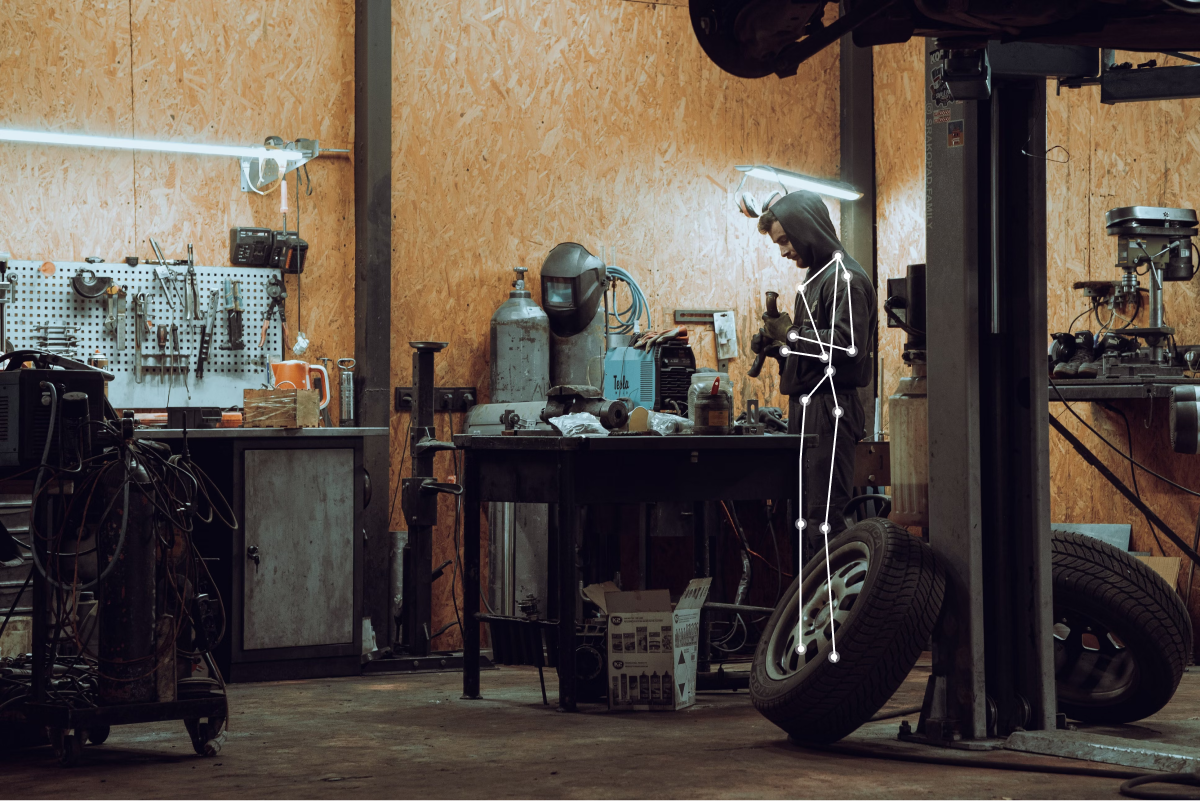

As the manufacturing industry evolves, so too does the imperative to enhance workplace safety. While essential, traditional safety measures can be complemented and improved by integrating artificial intelligence capabilities. AI is revolutionizing workplace safety by proactively identifying and mitigating risks.

AI consulting can evaluate the risk levels in different operations or areas of a facility by examining historical accident data, worker behavior, and environmental conditions. With advanced sensors and machine learning algorithms, AI can monitor environments in real time, detecting hazards such as unsafe machinery conditions, toxic gas leaks, or worker fatigue.

Source: Unsplash

Additionally, AI-powered systems can assist in training employees with virtual simulations, ensuring they are better prepared to handle dangerous situations. AI-driven tools reduce the possibility of accidents and create a safer workload, fostering a culture of safety and well-being for employees. For instance, you can integrate solutions like VP-Ergono that serve for evaluation and accident prevention, optimization, and design of work environments.

Safety in manufacturing is essential as it safeguards workers, prevents costly accidents, and supports seamless operations. Without proper safety measures, even the most advanced production systems can pose significant risks. Evaluation methods play a vital role in identifying potential hazards, assessing existing safety protocols, and ensuring compliance with industry regulations.

By 3D analysis of the entire body from video and camera footage, manufacturers can proactively address safety gaps, enhance operational efficiency, and foster continuous improvement. In the OWAS Method Evaluation, you can choose either prerecorded or live footage. The system uses a 3D model of the detected skeleton, showing a load graph on each body part. You’ll also see the AC Value for the specific action being analyzed, along with a graph displaying the values for the entire imported clip. Additionally, you can adjust the analysis by adding different weights and forces to see how they affect the evaluation.

Increased productivity

One of the fundamental advantages of AI in manufacturing is the boost in productivity and efficiency. AI-powered systems can investigate vast amounts of data in real-time, determining patterns and trends that human operators might miss.

This capability enables suppliers to optimize production schedules, streamline supply chain management, and diminish machine downtime. Thus, allowing the creation of factories that put less strain on the body. Predictive maintenance, for instance, uses AI algorithms to anticipate equipment failures before they occur, allowing manufacturers to perform maintenance only when necessary, minimizing disruptions and costly repairs.

Improved quality control

Quality control is paramount in manufacturing, and AI companies are redefining traditional methods. Machine learning algorithms can analyze images from production lines to detect defects or inconsistencies in products far more quickly than the human eye. This automation not only facilitates faster inspections but also reduces the rate of defective products reaching consumers.

As a result, industrial companies using AI can bolster their reputation for quality, leading to increased customer satisfaction and loyalty.

Source: Unsplash

Customized production and operation

In today’s market, consumers increasingly expect customized products tailored to their specific goals. AI enables manufacturing to drive more flexible production innovations that accommodate customization without sacrificing efficiency.

Data-driven decision making

The integration of AI into manufacturing processes empowers businesses with data-driven insights that apprise better decision-making. AI systems can process and analyze historical fabrication data, market trends, and consumer desires, allowing manufacturers to make informed strategic choices. Whether it’s modifying product designs or optimizing inventory management, having access to actionable intelligence helps manufacturers predict analytics.

AI in factory automation

Efficiency in machines has opened new horizons for manufacturing. Collaborative robots help reduce the number of personnel errors and simplify the production process. Unlike traditional robots, which typically operate in isolation, cobots are designed to work alongside human workers in a shared workspace.

Cobots can be easily redeployed, providing long-term cost savings by minimizing the need for specialized machinery or equipment. One of the primary advantages of collaborative robots is their ability to reduce the likelihood of personnel errors. By automating repetitive, complex, or dangerous tasks, cobots help minimize human mistakes, which are often the result of distractions and stress.

Source: Unsplash

Furthermore, AI affects robots by emulating human performance and speech. They can understand tasks and fulfill them cautiously, elevating operational efficiency with or without human work. There are also solutions for assessing the number of hours a worker at a factory, for example, automatic and quantitative analysis without observer’s subjectivity.

VP-Ergono’s burden analysis system is compatible with both recorded video files and live camera feeds. The skeletal and burden data generated by the analysis can be exported in CSV format, offering flexibility in how the data is used. Notably, VP-Ergono requires no specialized sensors or other equipment.

One of its key advantages is the ability to perform burden analysis using just a standard webcam and a PC. To illustrate the system’s efficiency, we compared the time and costs involved in analyzing video data for 100 employees performing manual tasks, using VP-Ergono versus traditional methods. The results show that by implementing VP-Ergono, businesses can significantly reduce costs related to task classification, analysis, and work hours. Summing up, when compared to the manual approach, the overall cost is reduced by approximately 98%.

Predictive maintenance

Systems equipped with AI algorithms predict excesses of stock, shortages, logistics routes, shipments, and machine repairs. AI-powered predictions help companies optimize resources, streamline operations, and reduce the risks associated with unexpected disruptions. By examining historical data and recognizing patterns, AI can predict these challenges before they develop into significant problems.

Forecasts management is the linchpin of manufacturing because it saves time, and reduces technical and surprise issues. Forecasting is also a good assistant because it will help workers navigate difficult or controversial situations. Additionally, AI-driven forecasting enables companies to optimize logistics, improve supply chains, and refine machinery maintenance schedules.

This proactive strategy helps avoid unpredicted disruptions that could disrupt production. As a consequence, companies can predict errors and work smart without breaches.

To know more about predictive maintenance benefits for businesses, please watch this video:

Artificial intelligence in manufacturing case study

One of the examples of leveraging AI in manufacturing is the VP-Ergono application. VP-Ergono is a cutting-edge posture analysis application that combines Al with ergonomics. It automatically analyzes posture by reading skeletal information from camera images and videos. The system displays improvement requirement levels based on the OWAS method and quantifies the load on each joint.

By utilizing the data from the analysis, VP-Ergono helps visualize the workload of on-site workers and contributes to accident prevention. Additionally, it enables the design and optimization of work environments based on ergonomic principles tailored to human body movements. Easily Switch between two Evaluation Methods: Moment Evaluation and OWAS Method Evaluation.

VP-Ergono performs the following evaluations:

- 3D analysis of the entire body from video and camera footage

In OWAS Method Evaluation, you can select prerecorded or live footage, make use of the 3D model of the detected skeleton, and see a graph where each body part’s individual load is displayed, a section where you can see the AC Value of the specific action on screen as well as a graph showing the entire imported clip’s worth of values. It is also possible to check how the valuation changes through selecting different added weights and forces acting on the body during analysis. - The analysis focused on movement by tracking changes in skeletal coordinates over time

In Moment Evaluation, you can select prerecorded or live footage of the target person, make use of the 3D model of the detected skeleton, and display load information for each body part as graphs or numerical data. Additionally, you can set parameters such as the person’s height and carried weight, which influence posture, enabling load analysis in various scenarios. - Automatic and quantitative analysis without observer’s subjectivity

VP-Ergono’s burden analysis is compatible with recorded video files as well as real-time camera footage. The skeletal and burden data obtained through the analysis can be exported to a CSV format, allowing you to use the acquired data freely. Moreover, there is no need for specialized sensors or equipment. One of VP-Ergono’s significant advantages is the ability to perform burden analysis using standard webcams and a PC. In other words, it offers relatively easy implementation and cost-effective, making it the desired solution in many industries.

By using a solution of this kind, you can cut the man-hours and costs required to analyze the video data for employees performing their work manually.

Wrapping up

The new era has been of smart, connected machines, in which people augment their work environment with intelligent collaborative robots. Adopting AI in manufacturing is about keeping up with technological progress, it is about reinventing operations to the challenges of the modern marketplace. From enhancing efficiency and quality assurance to diminishing costs and promoting security, a broad range of capabilities and applications, offering solutions that open new opportunities for innovation, the benefits of AI are compelling.

Therefore, AI and manufacturing go hand in hand to alleviate free workers from mundane tasks, attract more vendors and customers, and adapt to unexpected changes making your business more successful and productive.