The latest technologies drastically reshape a lot of industries and change the way business is done. The implementation of AI in inventory management becomes a crucial benchmark of the organization’s digitalization to stay competitive in 2021. More and more companies are going digital nowadays:

12% of respondents are already using AI technologies;

50% of organizations have adopted AI in at least one task/function;

65% of businesses encourage collaboration between businesses, data science, and analytics teams;

70% plan to enhance the AI technology usage in their warehouses;

91% of enterprises are already engaged in some form of digital initiative;

94% of retailers said that omnichannel fulfillment is a high/top priority for them.

If you don’t know how to reach a smoother performance, improve all the processes, and reduce errors that impact your revenue, then here we are to show you the ways AI and other tech solutions can solve such issues. Here you will find the AI use cases and benefits the business can get by implementing these and other technologies.

AI inventory management: what does it mean and why do you need it?

Today, Machine Learning solutions, Big Data, the Internet of Things (IoT), data science, and Artificial Intelligence inventory management systems, along with other high technologies, can not only increase the company’s efficiency but enhance customer experience and reduce costs. Yet, what does intelligent inventory management mean for you and why should your company use it?

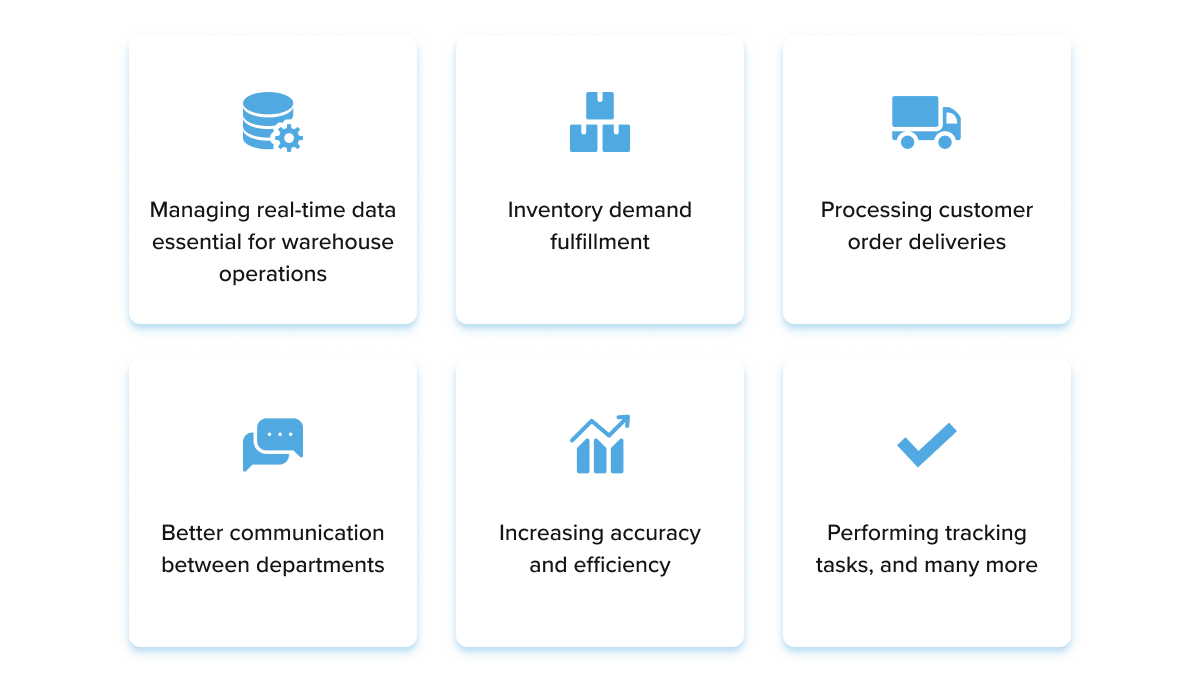

Business intelligence inventory management means using a definite AI-powered software or technology to manage warehouse stock in real-time with minimum effort and errors. Businesses can use sophisticated inventory management system that ensures new possibilities in:

Besides that, AI solutions help not only to structure received data for an error-free planning or demand forecast but provide aid in physical tasks like the reorganization of stocks, relocating and tracking items, and many more. Thus, the whole business performs better and more efficiently.

How AI will revolutionize inventory management: key ways to use it

Supply chain management can become more efficient at all stages by using AI and all the use cases described below demonstrate that. Seeing is believing so just check key ways to use artificial intelligence for optimizing your warehouse inventory and overall supply chain.

Demand forecasting and business modeling

AI makes demand forecasting easier. AI-powered demand forecasting can reduce errors by 20% to 50% in supply chain networks. So, with the implementation of AI and ML (machine learning), organizations can not only improve the accuracy of forecast results but optimize their replenishment plans.

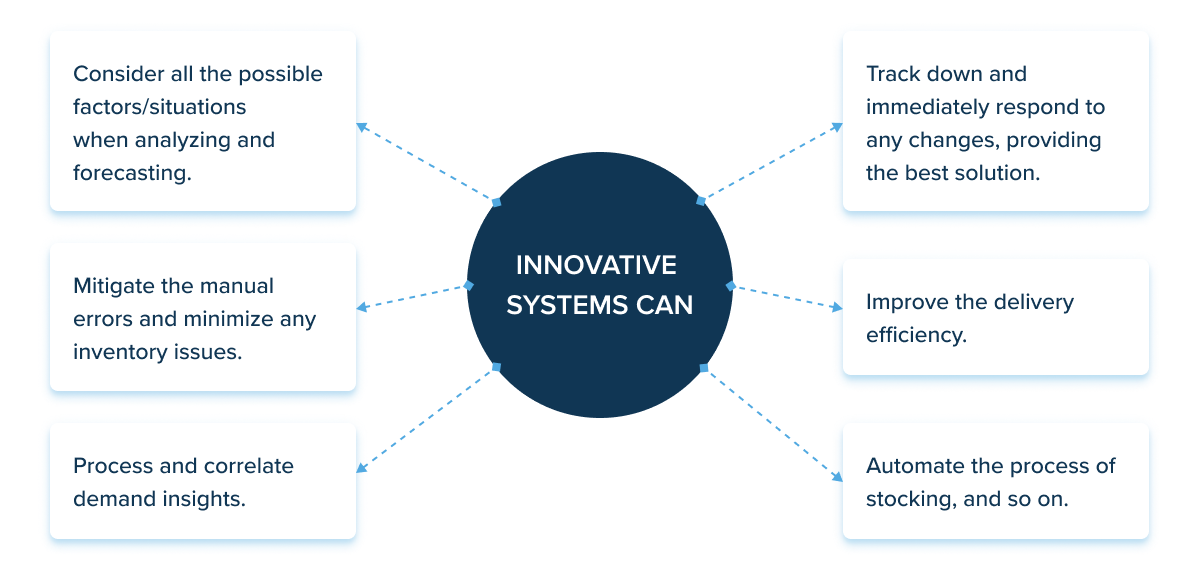

The state-of-the-art solutions can accurately analyze all the data gathered and correlate demand insights so that businesses can quickly respond to any changes in inventory needs and/or market demand.

Source: Unsplash

Using internal plus external sources (demographics, online reviews, social media, etc.), the technologies also enable enhanced forecasts based on real-time data. Thus, AI allows companies to easily discover specific patterns and predict near-future demands to optimize and simplify the overall process.

Data mining and processing

For data mining and turning it into solutions, AI is a rockstar. Not only do AI solutions collect, but analyze all the data accurately so that you can transform the insights into timely actions. Thus, AI allows you to predict and recommend products based on information collected through algorithms. Thus, having all the data and analysis results, businesses can understand customers much better and get insights about their interests/demands/pains to improve strategies and pre-plan stock products.

Delivering a personalized customer experience

AI can help you to leverage Big Data (that you have) to enhance customer experiences. AI-based software enables companies to use the data to level up personalization by tailoring products and services that are highly relevant to individual consumers. Thanks to that, businesses can create custom user experiences around the specific customer’s demand.

Source: Unsplash

Inventory management and order fulfillment

Do you know that inadequate or wrong stocking can be pretty harmful to your business? AI solutions help mitigate the risks of over/understocking. Yes, thanks to the ability of intelligent systems not only to stock and deliver products but to control, forecast, and plan, your company can reduce costs. And that’s because innovative systems can:

Materials procurement

Inventory management using AI can be used for reducing waste and increasing profit. AI analytics consider any small detail from the very first stage of quoting to the supply chain. Intelligence inventory management software can automatically order the right amount of materials required to fulfill orders. That enables organizations to make well-informed business decisions.

Using AI-powered robotics in the warehouse

AI-powered robots are not a fantasy, but a reality. They are already used for automation of the warehouse’s daily tasks by such giants as Amazon. It’s expected that by 2023 the robot automation market’s value will be over 10 billion U.S. dollars. And that’s thanks to a number of benefits that put robots over human staff, especially in routine operations.

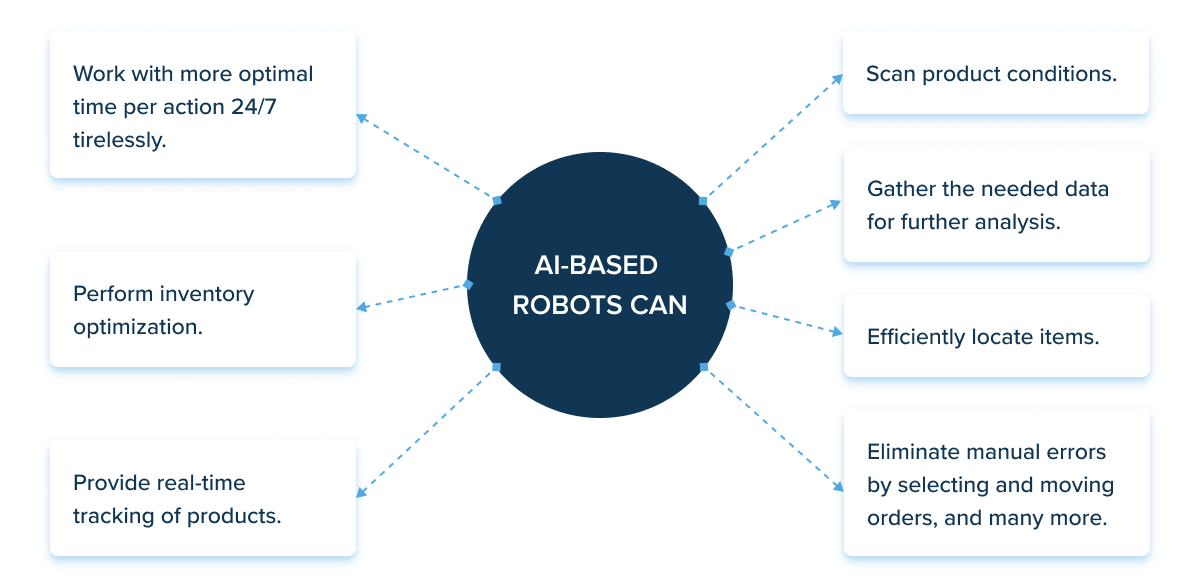

AI-based robots can:

Thanks to the ability to gather and analyze the data for predicting the demand patterns and suggesting optimal delivery routes, AI robots have become a potent tool that can completely automate internal processes in any warehouse.

Benefits of improving inventory management with AI

Knowing how you can use AI for improving inventory management, it’s high time to find out what benefits businesses can get. Below we outlined what exactly you can expect to get by implementing the latest technologies. So, let’s check the impact of AI on inventory management.

Reduced storage and shipping costs

Poor inventory management results in a loss of more than $300 billion in revenue. By improving inventory management with AI, businesses can slash costs and improve cash flow. Prioritization of critical processes to resolve bottlenecks, mitigate costly risks, and meet ever-changing demands is the next strong feature of AI inventory management software.

Thus, the technology helps eliminate the additional costs of excessive storage space rental, unsold products, and unsatisfied customers. At the same time, AI also allows you to make additions to your inventory or product line-up that can be done immediately, with little or even no added cost.

Optimized stocks

Shortages, delays, over/under-stocks, and other issues that affect business revenue can occur because of planning errors and/or inadequate stock monitoring. Thanks to the accurate forecasts, demand analysis, and other crucial insights available with AI-based inventory management systems, you can prevent such issues and optimize stocks.

AI has an ability to deliver instant alerts on delay in delivery, low inventory, incidents, collect and analyze data that help businesses:

- Leverage and react to changing demands on time

- Plan the stocking right

- Find and organize efficient transportation

- Streamline deliveries and boost their efficiency

- Automate the stocking and fulfillment processes, and so on.

Source: Unsplash

Not only can such stock optimization reduce costs, but improve the collaboration of departments, increase efficiency, and enhance consumer satisfaction. As a result, the company gains bigger revenue.

Waste control

It’s associated with the previous point. So, maintaining optimum stock levels to avoid stock-out or overstock issues is the biggest challenge for organizations. Applying Machine Learning to business and using intelligent inventory management systems, it’s possible to:

- Identify and track products

- Take an action when items are overstocked or under-stocked beyond a pre-defined threshold

- Maintain the right inventory levels for each product

- Generate reports that can help you avoid product spoilage/waste, etc.

Thus, your company can better use limited physical space, operate more sustainably, and, as a result, reduce storage costs.

Improved monitoring procedures

Automated inventory monitoring is one of the key features of AI inventory management systems. Using the technology for tracking inventory, businesses reduce manual errors, improve monitoring procedures, and keep inventory in the optimization stage.

Source: Unsplash

For example, AI robots can sort, move, and arrange items in the inventory. When featured with advanced technologies such as computer vision and smart sensors, they can detect obstacles and label items with the highest accuracy, improving monitoring procedures to a great extent.

Reduced demand-supply gap

Unified with data analytics, AI can accurately predict the demand for products to maintain the optimal stock level always. Thus, the system can process the data regarding the demand for seasonal products for the last few years to forecast the demand for these products in the upcoming season with higher accuracy. What’s more, AI inventory management software can even order the needed number of products automatically, taking into account all the factors like weather, delays, etc.

Optimized supply chain

The tendency is that we shift from simple reactive intelligence to predictive, adaptive and continuous learning systems. Such solutions are aimed to drive better and data-based decisions for continuous improvements using machine learning and AI in the supply chain. Thus, AI and machine learning vendors can seed the much-needed exceptional agility and precision in supply chain optimization so that the companies can decrease costs where repetitive manual tasks can be automated.

Final thoughts

Today, AI and inventory management form a unified whole for the digitization of the supply chain. Currently, artificial intelligence inventory management offers many benefits like:

- Better warehouse logistics and productivity

- Optimized costs of operation and resources

- Improved communication within the warehouse

- Reduced errors

- Increased turnover, customer satisfaction, and retention, and many more.

Thanks to custom artificial intelligence software development, businesses can get an intelligent inventory management system that meets their needs most of all. By choosing the right AI company, you can build a tool that will help you achieve settled objectives and grow your business faster.

Author Bio

Alexey Kutsenko is CMO at DDI Development, which provides custom web & development services to clients worldwide. Alexey has vast experience in building marketing strategies for various clients, defining the client’s needs, and leading digital marketing strategies in the company.

Leverage AI for Effective Inventory Management!

Need help in solving inventory management challenges? Contact our team and we’ll consult you on how to analyze consumer demand, prevent over and under stocking, and increase sales.