The modern supply chain is a mixed bag of businesses, workforce, and software. AI in supply chain and AI-based supply chain management can usher in elements of flexibility combined with profit into this chaotic landscape.

Artificial intelligence in supply chain management is also a welcome shift because of the pandemic. COVID-19 has laid bare the unpreparedness of distribution chains for emergency situations. Thus, only 2% of companies said they got prepared for the pandemic. Another 57% of suppliers reported serious disruptions that required long recovery.

Besides, the need for more sustainability is acute far beyond the pandemic. And we haven’t yet gotten this issue in gear. It’s a bunch of long-simmering problems. But we can crack them all by introducing AI in supply chain and logistics. Let’s find out the hows and whys of artificial intelligence transportation and supply chains.

What is AI in logistics and supply chain ecosystem?

Using AI-based supply chain management has nothing to do with the futuristic renderings of science fiction movies.

AI in the supply chain refers to smart machines capable of performing problem-solving tasks. Usually, machines automate processes so they can operate with no human participation.

Companies using AI in the supply chain aim to make SCM more:

- Instrumented – machine-generated data flowing out of IoT devices;

- Interconnected – extensive connectivity for better decision-making;

- Intelligent – smarter and more precise assumptions with the help of advanced analytics and modeling.

Benefits of artificial intelligence in supply chain management

Today, valuable data dominates all industries. And we can’t imagine an effective logistics system without extensive databases. A well-established order processing system and communication between agents generate mountains of data as well. Over the past few years, next-gen machine learning services have overhauled logistics and access to customers. So, let’s see what benefits of intelligent distribution channels have already surfaced in 2021.

Source: Unsplash

Improved end-to-end visibility and response times

Using AI and supply chain allows companies to gather relevant and past data from multiple connected devices. These also include SCM, ERP, and CRM systems. This way, organizations can glean broader and deeper performance evaluations. Deep learning supply chains can also help expect problems and minimize the impact on the distribution channels.

Predictive analytics

Another competitive advantage of AI in supply chain is demand forecasting. This became possible with the help of predictive analytics platforms and Machine Learning models. The latter solves supply chain process optimization problems and helps achieve optimal inventory levels.

Simplified inventory management

Well-organized inventory management is the foundation of the supply chain. Computer and machine vision software can minimize the manual input and create accurate forecasts. The AI system can analyze and interpret data in real-time, thus monitoring the inventory and stock in warehouses or on store shelves.

More insight into the future

Another thing you can do with Artificial Intelligence is to forecast future trends. The same goes for customers’ developing needs and demands. The AI ecosystem allows for the supreme level of agility. With ML algorithms, you can determine clients’ needs before they even know it.

Improved customer experience

Artificial intelligence and Big Data have also taken the customer experience to a whole new level. Smart solutions allow for the personalization of the customer experience. For example, DHL provides a voice-activated means of tracking DHL Express shipments via your Alexa device. Hence, consumers can simply ask Alexa about their order and find out information.

Source: Unsplash

Overall, Artificial Intelligence in logistics and supply chain management keeps companies ahead of the curve.

Big Data to amplify the use of AI in supply chain

A cognitively enabled supply chain owes its existence to Big Data and Data Science. The causality is simple. Your supply chains generate big data. Big supply-chain analytics and AI transform that data into business insights.

What is big supply chain analytics?

Big supply chain analytics is a set of tools, processing systems, and algorithms. They support decision-making throughout the logistics lifecycle. This field of knowledge combines data and quantitative methodologies. As a result, it enriches the dataset beyond the usual internal ERP and SCM data. Big analytics also bring new statistical methods to the table. These two features help produce fresh insights to improve front-line and strategic operations.

Source: Unsplash

Landscape of Big Data and AI in supply chain management

Let us explain the power of Big Data and Intelligent Technologies in real-world examples. Investments in analytical architecture have proved their viability in various areas. It supports supply chain management at each stage.

Planning

Inventory managers get an estimated volume of sales with the help of big data. The latter combines historical data with predictive analytics to forecast supply and demand. Thus, prediction by evaluation allows companies to predict future demand without guesswork. It allows manufacturers to reduce costs by eliminating unnecessary supplies.

Sourcing

Procurement costs account for around 43% of the total costs. Hence, organizations are looking for a smart way to reap more savings. Big Data and Artificial Intelligence in procurement and supply chain find efficiencies in contractor performance. The technologies source optimal pricing to avoid extra spending.

Execution

Big Data ecosystems help maximize resources to improve production capacity. Thus, IoT sensors coupled with AI can predict the best maintenance schedule.

Delivery

At the delivery stage, smart data systems ensure a smooth logistics process. They help find optimal routes and ship the product in time.

Return

Reverse logistics also benefits from data-powered software. Analytics can help reduce return costs and ensure trouble-free returns. The data-first future seems bright. But there are currently some barriers to seeing the result.

AI in supply chain planning: main restraints

It’s easy to get carried away with the potential of Artificial Intelligence in supply chain market. Yet, there’s more to that than a simple AI transition from traditional systems.

Upfront Costs

The question of ‘how much’ is among the main stumbling blocks. The major challenge is that all AI systems should be customized to operate in sync. It means that shippers and warehouse providers have to splurge for bespoke hardware and software. Hence, the cost of AI-specific hardware requires an impressive initial investment.

Employee Training

The rapid evolution and growing viability of AI translate into evolving skills. This will cost logistics partners and others involved in training expenses. They will have to team up with the AI provider to provide a training solution during the adoption phase.

Source: Unsplash

Lack of Valuable Data

Up to 73 percent of all data within an enterprise goes unused for analytics. It means that most companies don’t have effective master data management in place. And since computational processes need clean and real-time data, its absence impedes the adoption process.

Six AI use cases in supply chain

Now let’s have a glimpse of examples of artificial intelligence in supply chain management.

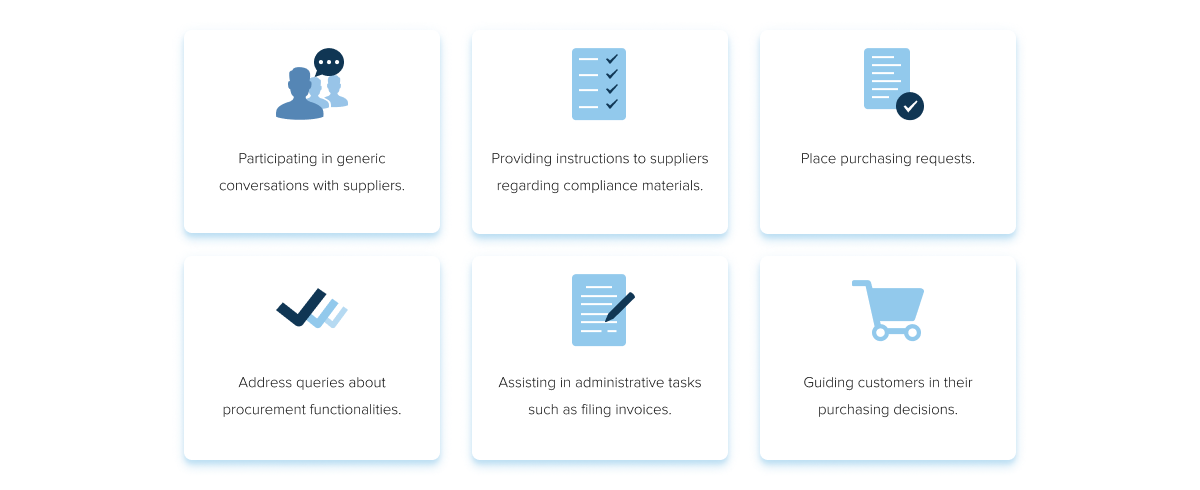

Chatbots for operational procurement

Traditionally, customers have to spend hours placing a query about an order or shipment. Procurement chatbots or procuebots can eliminate the hassle of bouncing from one department to another.

Smart assistants can address a simple query and provide all associated information regarding the order. Other related tasks include:

Streamlined E-commerce

Artificial Intelligence is also among the most valuable E-commerce solutions. Online retailers leverage big data analytics and Ml algorithms to streamline their management processes. Intelligent retail tools also help pick the best shipping and fulfillment options for any transaction. Thus, both customers and retailers get the cheapest and quickest delivery methods.

Source: Unsplash

Fulfillment technologies can also maintain track of consumer preferences. Real-time delivery tracking, and updates and status reports, are also available for smart tools. For example, Flipkart uses Machine Learning E-commerce to automate distribution network management. Smart algorithms help predict delivery dates and drive warehouse automation. The innovations also address frauds and make sense of complex Indian addresses. Flipkart implements robotics that helps deliver orders in time.

Enhanced inventory management

Inventory management doesn’t come down to storing and delivering items. It generates and feeds on substantial amounts of data to be effective and profitable. Therefore, efficient data management is crucial to expect demand and AI to supply optimization. Companies using smart systems can optimize inventory management to meet consumer demand. Smart inventory control also assists in processing supplier and production orders, reorder points, and others.

Source: Unsplash

Big Data and Artificial Intelligence yield a real-time overview of operations. This allows pinpointing bottlenecks that hinder distribution processes.

For instance, Amazon has proven an AI stranglehold on inventory management. The company uses Big Data and Artificial Intelligence at “fulfillment centers.” There, they optimize inventory according to the location of its vendors and customers. This way, the adoption of data-driven technologies reduces distribution costs and fine-tune inventory based on local preferences.

RFID Tags

Another inventory-related breakthrough is the adoption of radio-frequency identification or RFID. Essentially, this technology incurs information required for the unique identification of a particular object remotely. Thus, the reader captures digital data embedded in RFID tags via radio waves.

If you couple RFID tags with Machine Learning algorithms, it can ensure accurate identification to date. Smart labels also enable remote communication of inventory information with increased accuracy and speed.

For example, Zara encodes each garment with RFID tags to track it throughout the distribution process. When online sales ramp up, RFID helps check if an item is in stock at the local store.

Autonomous vehicles for shipping

Artificial Intelligence transportation has been holding the stage on the market. The main reason for its rise is economic gain. Thus, AI-based network management presents ample opportunities for lowering freight costs. With full autonomy, operating costs can drop to about 45 percent. This number equals $85 to $125 billion for the US for-hire truck industry.

Automation will grant the ability to flex with peak demand and reduce lead times. Autonomous transportation will also help eliminate driver shortages and improve fuel efficiency. Global enterprises were fast enough to jump on the self-driving train. For example, AB InBev, the famous brewing company, began testing Embark unmanned trucks in April. Apple and Amazon are also spearheading the technology. Both companies have secured several autonomous driving patents over the last few years.

ML for supplier selection and relationship management (SRM)

Selecting the supplier and maintaining a fruitful collaboration is a common problem in the industry. AI-powered analytics has enhanced supply chain sustainability, CSR, and supply chain ethics. These tools can now provide forecasts on risks and uncertainties related to procurement. The time spent on research and risk assessment can now be repurposed to other critical areas.

Machine Learning algorithms can effectively process operational SRM data sets. Thus, any information, such as supplier assessments and credit scoring, lays the ground for successful analysis. AI-field algorithms then render the data active and offer multiple ‘best supplier scenarios’.

Top companies using AI in supply chain

As usual, A-list enterprises lead the global market by example. Today, quite a several companies are betting on the duo of supply chain management and AI. Let’s zoom in on some of the most eminent players in the tech game.

Salesforce – genius like Einstein

In 2016, Salesforce unveiled its innovative AI service. It now goes under the name Einstein. The intelligent tool improves performance throughout the entire distribution network.

Later, Salesforce.com stepped up the game with its Einstein Bots for Service. Thus, Salesforce customers can now submit customer service requests to bots. The latter uses a combination of machine learning, NLP, and historical data to decide. Salesforce Einstein also automates data entry so that every sales moment is transparent.

Oracle – adaptive intelligent apps

This tech giant is well known for providing cloud solutions. These enable faster time-to-business insights and connected infrastructure. Oracle offers adaptive intelligent applications to make businesses data-driven. Thus, cloud-powered apps learn from billions of consumer profiles. The insights help applications to find the best distribution options across particular geographic locations.

Amazon – AI-first company

No list of tech-savvy companies would be complete without this sales titan. Amazon is already leading the supply chain sophistication.

Recommendation systems, chatbots, and predictive distribution processes are just a few examples. The company operates a robust AI flywheel, where AI innovations in one part of the firm fuel the work of other teams.

Amazon also embraces the same technologies found in self-driving cars. Thus, multiple applications of computer vision technology and deep learning complement AI in supply chain planning. The technology can elicit when products are returned to the shelves and tracks them in the virtual cart.

Overall, Amazon's refined use of AI and ML for demand prediction is the lynchpin of its E-commerce strategy.

DHL Logistics – great IDEA for E-fulfillment

Supply chain management and AI are finding strong adoption within the fulfillment process at DHL. Its IDEA ‘plug and play’ solution relies heavily on algorithmic analysis and data science. These help the courier service to optimize choosing routes and warehouse staff allocation.

Expert systems also group orders logically. Intelligent task planning highlights more time-sensitive shipments and optimizes workload distribution for warehouse staff. The IDEA solution decreases error rates and reduces employee training timeframes.

The software reduces traveling distance for warehouse workers by% 50. The productivity gains are also noticeable – up to% 30 in terms of individual DHL locations.

Getting ready for a more intelligent future

Only 12% of supply chain profi report the deployment of AI as a supply-chain management tool. But this tendency is going to accelerate its pace. The market of Artificial Intelligence in the supply chain will reach $12 billion in 2027.

So, those companies who strike hot iron will reap the major benefits. There are countless possibilities for smart innovation in distribution. By embedding these tools into the existing infrastructure, organizations will reach the greatest cost efficiency and visibility throughout the whole industry ecosystem.

Implement AI in supply chain management!

Want to improve your supply chain business with cutting-edge solutions? Contact us, and we’ll set up a call.